1. 📞 Client Requirement Intake

- Gather initial information:

- Functional description of the product

- Technical specifications (voltage, current, communication protocols, dimensions, etc.)

- Block diagram (if available)

- Budget and timeline expectations

- Sign a Non-Disclosure Agreement (NDA) if necessary

2. 📊 Technical Analysis & Consultation

- Engineers assess feasibility and suggest optimal solutions

- Recommend components and technologies

- Define project milestones, deliverables, and estimated schedule

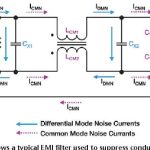

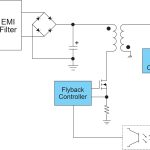

3. 🧩 Schematic Design

- Create the circuit schematic using professional tools ( KiCad is prefered)

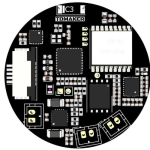

4. 🧭 PCB Layout Design

- Place components and route traces

- Optimize for size, thermal performance, and manufacturability

- Submit layout for Client Review – Round 1

- Apply revisions based on feedback

5. 📦 Design Package Delivery

Client receives:

- Schematic files (.SCH or PDF)

- PCB layout files (.PCB or Gerber)

- Gerber + NC Drill files for fabrication

- Bill of Materials (BOM) – component list

- Pick and Place file – for automated assembly

- 2D/3D PCB renderings (if requested)

- STEP file – for mechanical integration

6. 🧪 Prototype Fabrication & Assembly (optional)

- Manufacture sample boards (2–5 units)

- Assemble components

- Perform functional testing ( done by customer if firmware based from customer development)

- Ship prototypes for Client Review – Round 2

7. 🔁 Feedback Loop & Finalization

- Client tests prototypes and provides feedback

- Engineers fix bugs, optimize performance, update design and notice customer about extra cost if any.

- Final design is prepared for mass production

✅ Summary of Deliverables

| Deliverable | Purpose |

|---|---|

| Schematic (.SCH/.PDF) | Circuit understanding |

| PCB Layout (.Gerber) | Manufacturing the board |

| BOM | Component sourcing |

| Pick & Place file | Automated assembly |

| STEP file | Mechanical integration |

| 2D/3D renderings | Visualization and presentation |

| Prototype boards | Real-world testing |

Leave a Reply